Sale

SKU:

Categories: Lithography, Sawatec Instruments, Spray Coaters

- Description

Uniform coating of 3D microstructures

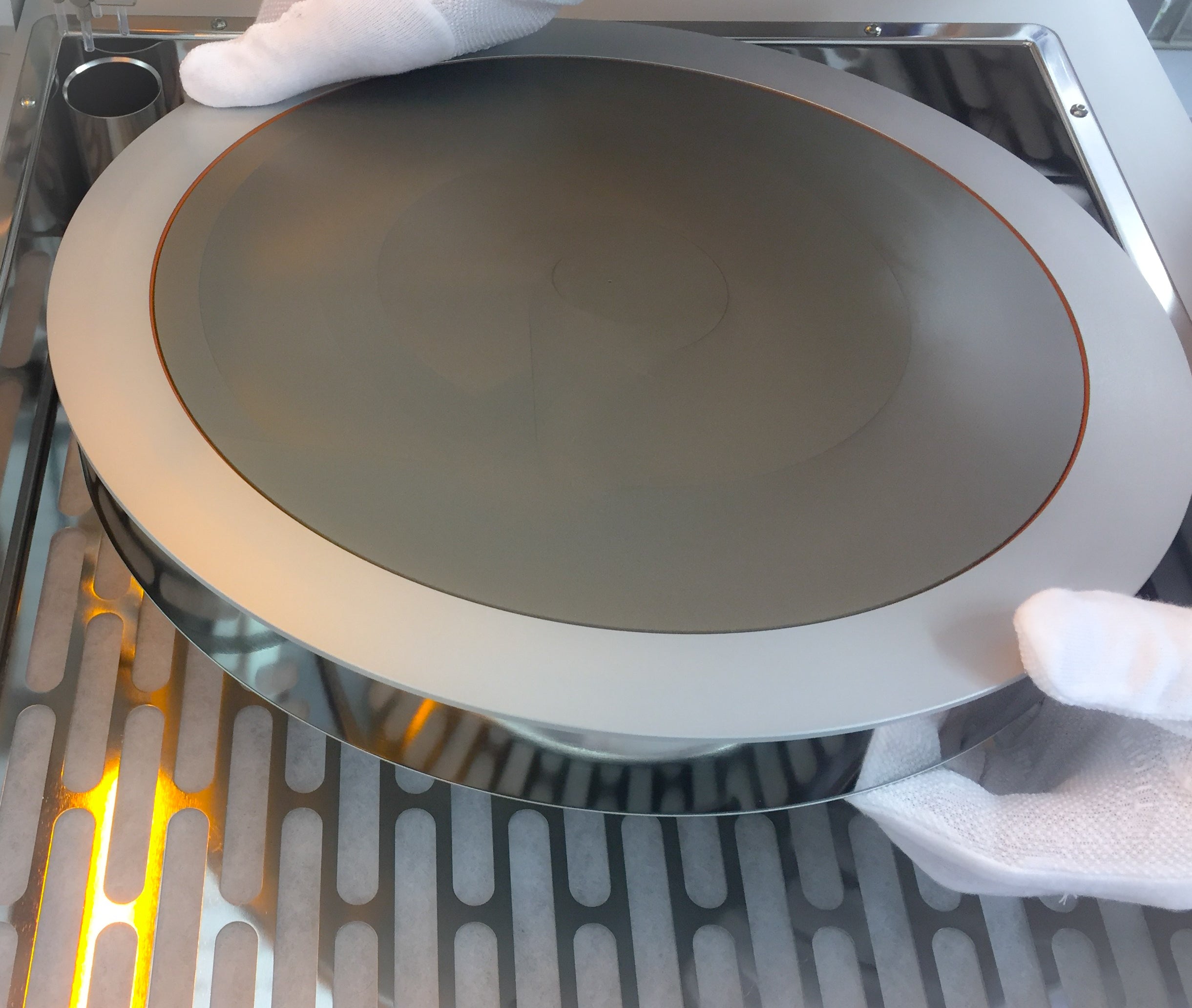

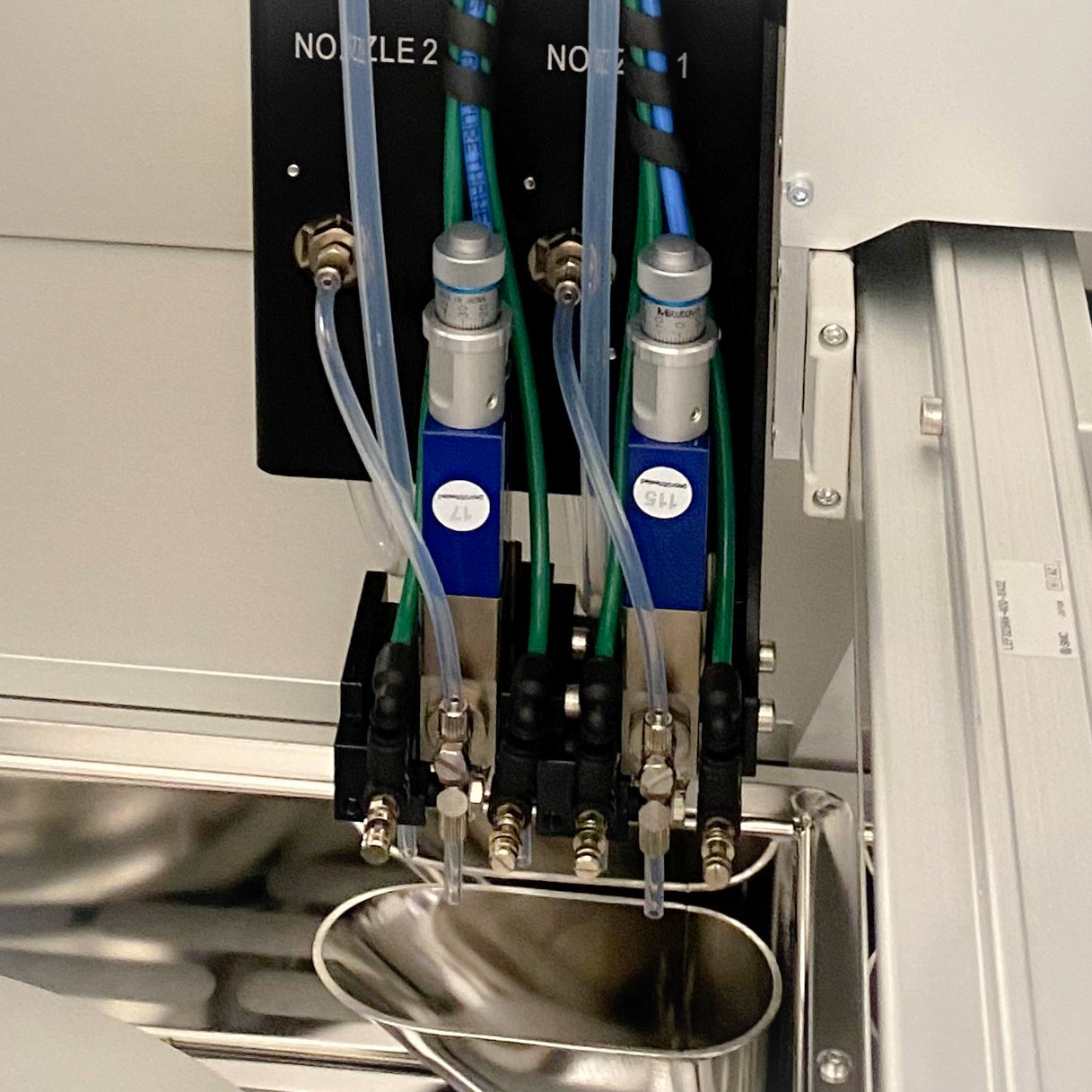

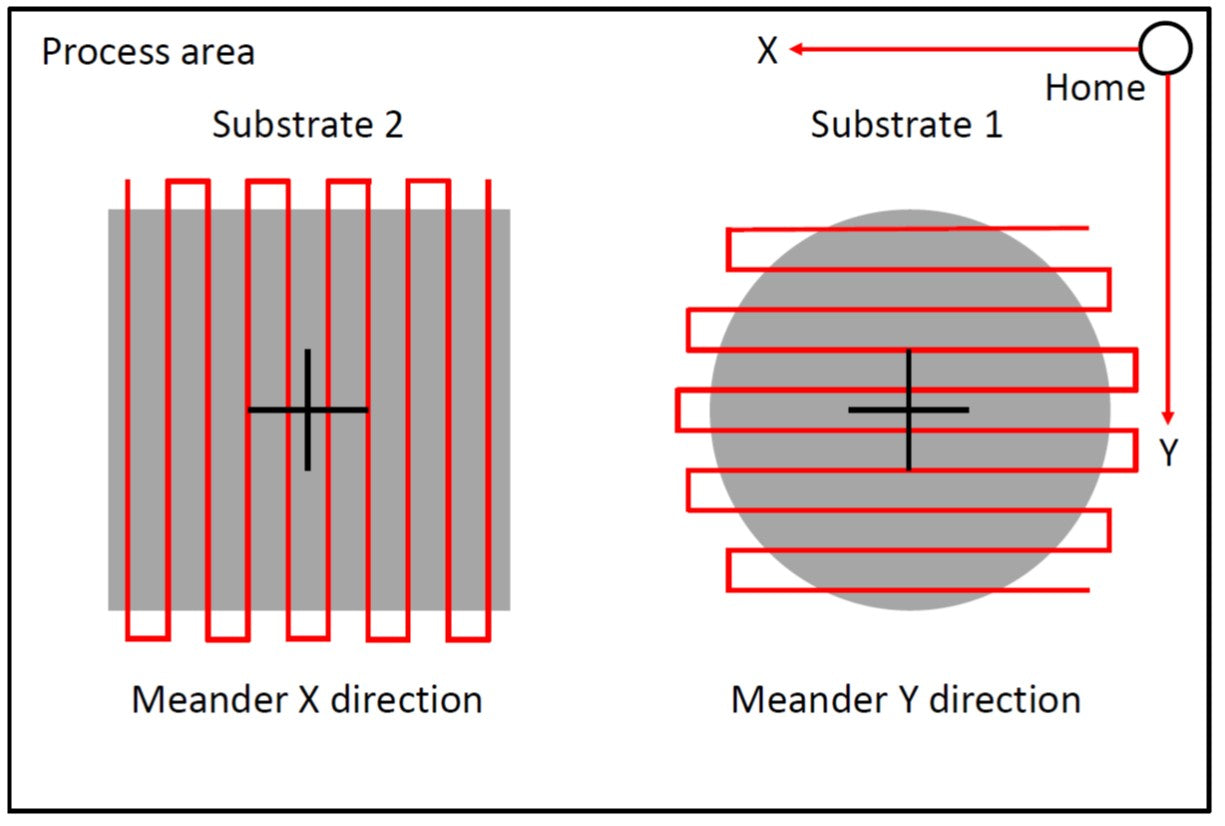

In conjunction with low-viscosity photoresists (e.g. Shipley 1813, AZ 4999, AZ 9260, TI Spray etc.) that are particularly suited for spray coating, the process-optimised spray nozzle generates extremely fine droplets. Spray coating takes place by means of a loop-shaped spray pattern in a closed process chamber, thus ensuring uniform coating across the entire substrate surface and a high level of repeatability. The spray nozzle spacing, which can be adjusted as a function of the process, improves the distribution of the spray coating for specific topographies and increases coating versatility. Both round and square substrates, up to 8 wafers at a time, can be coated.

The iSPRAY-300 spray coater is designed for wafers with a maximum diameter of 300 mm or for 12 × 12 inch substrates. The high-precision instruments are available as mobile cabinet.

100% Original and Quality

100% Original and Quality

24 Months Guarantee

24 Months Guarantee

Recently Viewed

Choose Ezzi Vision

Vacuum, Lithography, Thin-Film Experts

Experience top-tier repair and maintenance services for glovebox and vacuum equipment, backed by industry expertise across Australia.

Contact Us