Applications

Bio-fuel Research and Manufacturing

A variety of vacuum systems, such as dry vacuum pumps, turbomolecular pumps, leak detectors, vacuum gauges and components are used to optimize performance across applications, ranging from light duty to the heaviest duty processes.

Dry Pumping Technology

A key advantage of dry pumps, which include roots, claw and screw technologies, such as Edwards’ new CXS vacuum pump, is that they do not use water or oil for sealing or lubrication of the vacuum stages. As a result, they are economical to run, enabling users to optimise their vacuum processes and minimise overall cost of ownership.

Petro Chemical

Edwards is a world leader in the design, technology and manufacture of dry vacuum products for process applications in the chemical, speciality chemicals and pharmaceutical industries. Our application expertise allows us to provide you with reliable vacuum solutions and to support you all the way, from the choice of your standard or customised system to long-term service agreements to give you complete peace-of-mind.

Pharmaceutical & Medical Manufacturing and Research

Pharmaceutical and medical research provides new and innovative treatments to enhance well being and prosperity. Pharmaceutical R&D, as well as product and medical devices manufacturing is a technically demanding industry, and uses vacuum technologies in various key applications.

Scientific Research

Vacuum pump technology is used extensively within all the subfields of physics. For example, turbomolecular pumps are widely used in high-energy physics, fusion technology and general UHV research. Also mechanical roughing vacuum pump technologies are used by physicists, including: Rotary vane pumps, rotary piston pumps, dry semiconductor pumps, dry scroll vacuum pumps, diaphragm vacuum pumps and roots blower booster vacuum pumps. They all have an established role in physics research of today.

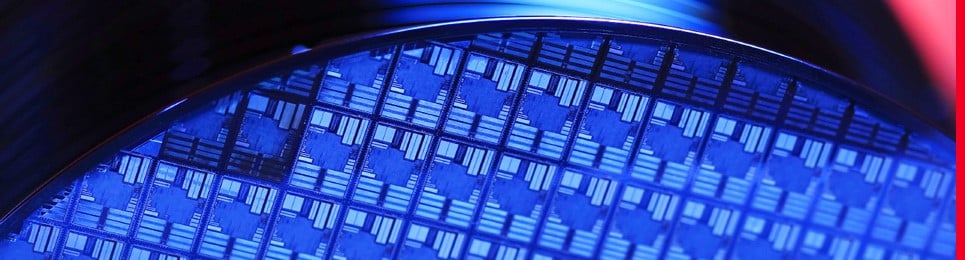

Semiconductor Manufacturing and Research

PCs and cell phones, such as smart phones, laptops, and tablet computers have gotten to be key in our data age. The chips fuelling these gadgets are made through repeated steps of vacuum processing

Solar Cell and Photovoltaic Manufacturing and Research

Solar cells or photovoltaic exhibits are created in vacuum based technology processes. Thin film manufacturing and research is at the focal point of the solar energy industry. Turbomolecular pumps are utilized for ultra-clean and high dependability vacuums required in manufacturing. Vacuum technology applications incorporate silicon cell and thin film panel manufacturing, film deposition, and use of mass spectrometers.

Synchrotrons

Synchrotron radiation is used in a wide range of research – for example, the Diamond synchrotron is being used by one team of researchers to study the causes of diseases such as Alzheimer’s. We are delighted that our equipment is contributing to such ground-breaking studies.

Tool Coatings

Physical Vapour Deposition (PVD) machining and tooling coatings are widely used to increase the life and productivity of production cutting tools. Chemical Vapour Deposition (CVD) is an atmospherically controlled process conducted at elevated temperatures in a CVD reactor Thermo reactive Diffusion (TD or TRD) is a high temperature coating process for producing metal carbides, typically vanadium carbide. Ezzi vision sells and services a full range of vacuum pumps to the exact requirements of these coating applications.

Glove Box Solutions

Choose Ezzi Vision

Vacuum, Lithography, Thin-Film Experts

Experience top-tier repair and maintenance services for glovebox and vacuum equipment, backed by industry expertise across Australia.

Contact UsFrequently Asked Questions

What types of industries do your vacuum solutions serve?

+Our Industrial Vacuum Solutions cater to a diverse array of sectors like pharmaceuticals, food processing, manufacturing, and academic research labs. Whether your focus is on achieving precise environmental conditions in scientific studies or needing durable systems for production lines, our technology is designed to elevate your productivity and streamline operations seamlessly.

Can Ezzi Vision customise vacuum solutions for specific business needs?

+Definitely! At Ezzi Vision, we pride ourselves on tailoring Vacuum Solutions to fit your operational needs precisely. Our approach involves a close partnership with you to fully understand your processes and design a system that meets and enhances your workflow efficiency and outcomes.

How does Ezzi Vision ensure the reliability of its vacuum products?

+At Ezzi Vision, our commitment to quality is paramount. Every Scientific Vacuum Pump and industrial system we provide is thoroughly tested to guarantee top performance and dependability. Additionally, with support centres in Melbourne and Sydney, expert help is always within reach to keep your systems running smoothly.

What support does Ezzi Vision offer after purchasing a vacuum system?

+Post-purchase, you’re not left on your own. We provide extensive ongoing support through detailed service contracts covering standard and preventive maintenance to ensure your systems are always in top shape. Our dedicated technicians are also on standby to offer prompt assistance and ensure your operations never skip a beat.

How can I get a quote for a vacuum solution from Ezzi Vision?

+Getting a quote from us is straightforward and hassle-free. Check out our website or give us a quick call. We will chat with you about your specific needs, offer professional guidance, and prepare a customised quote designed to fit your budget and exceed your expectations. Let’s enhance your operational efficiency together!